This case study discusses the implementation of SEA Vision’s OCV Multi and Databox solutions for a pharmaceutical manufacturer in Europe. Integrated with a Marchesini BL-H235 labeler and MA300 cartoner, the solutions aimed to ensure full inspection of variable data, label presence, and non-serialized codes, ultimately enhancing quality, compliance, and operational efficiency.

Read the full case study⬇️

Challenges

The manufacturer required an automated inspection system for its bottlepack line, which packages various bottlepack formats into cartons. Key challenges included:

-

Variable Data Accuracy on Labels

Ensuring batch numbers, expiry dates, and other variable data were correct and legible. -

Label Presence Verification

Confirming every bottlepack was properly labeled before cartoning. -

Non-Serialized Code Verification

Ensuring that non-serialized codes on cartons and leaflets were printed correctly.

Manual inspections could not keep pace with high production speeds while guaranteeing the accuracy required for regulatory compliance and product integrity.

Solution

SEA Vision deployed its OCV Multi and Databox solutions integrated with the Marchesini BL-H235 labeler and MA300 cartoner to address these challenges:

OCV Multi on Labeler BL-H235

-

Variable Data Verification

Four cameras (two on each labeling head) inspect the variable data printed on labels. Any incorrect data automatically triggers rejection.

-

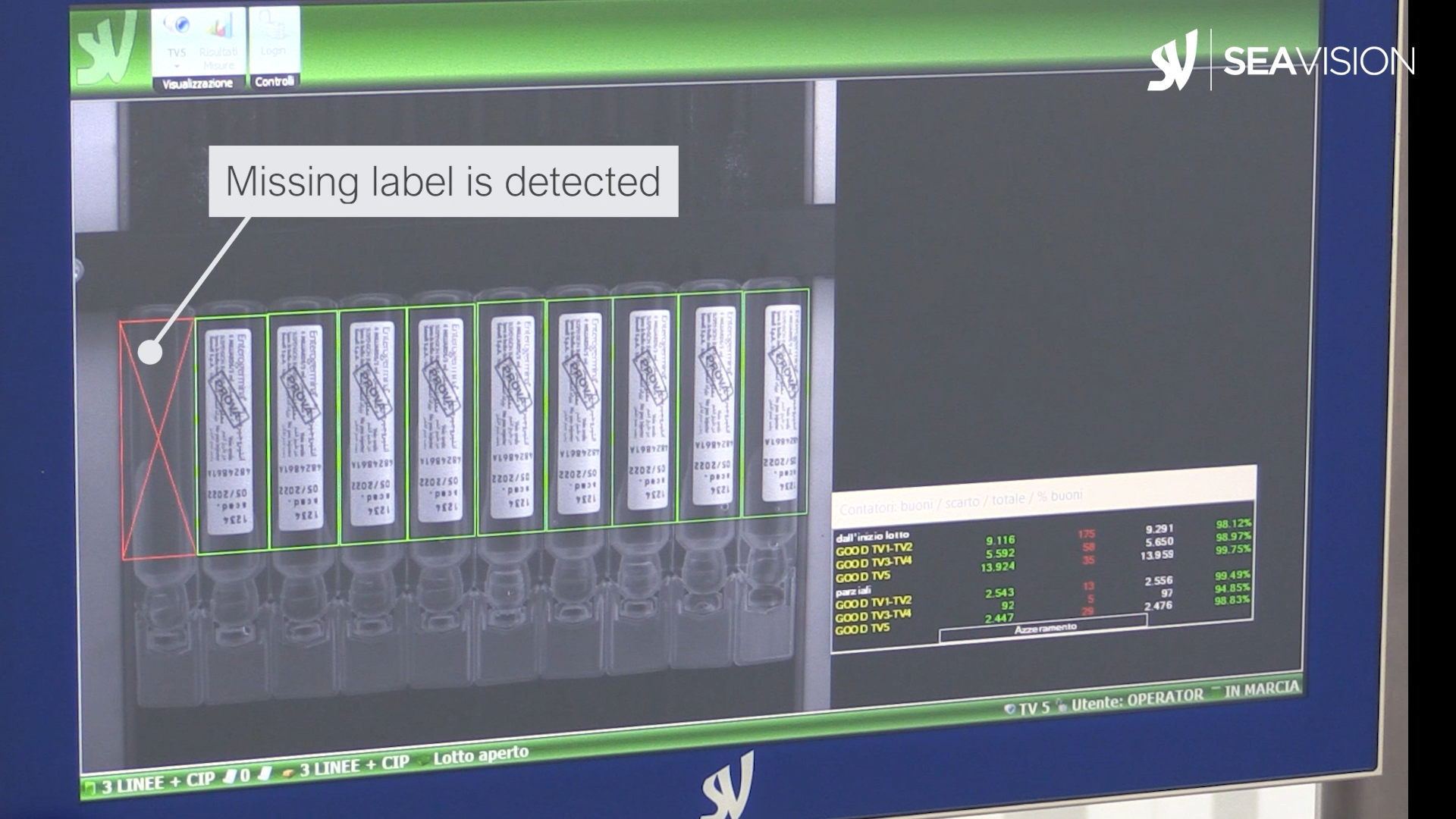

Label Presence Check

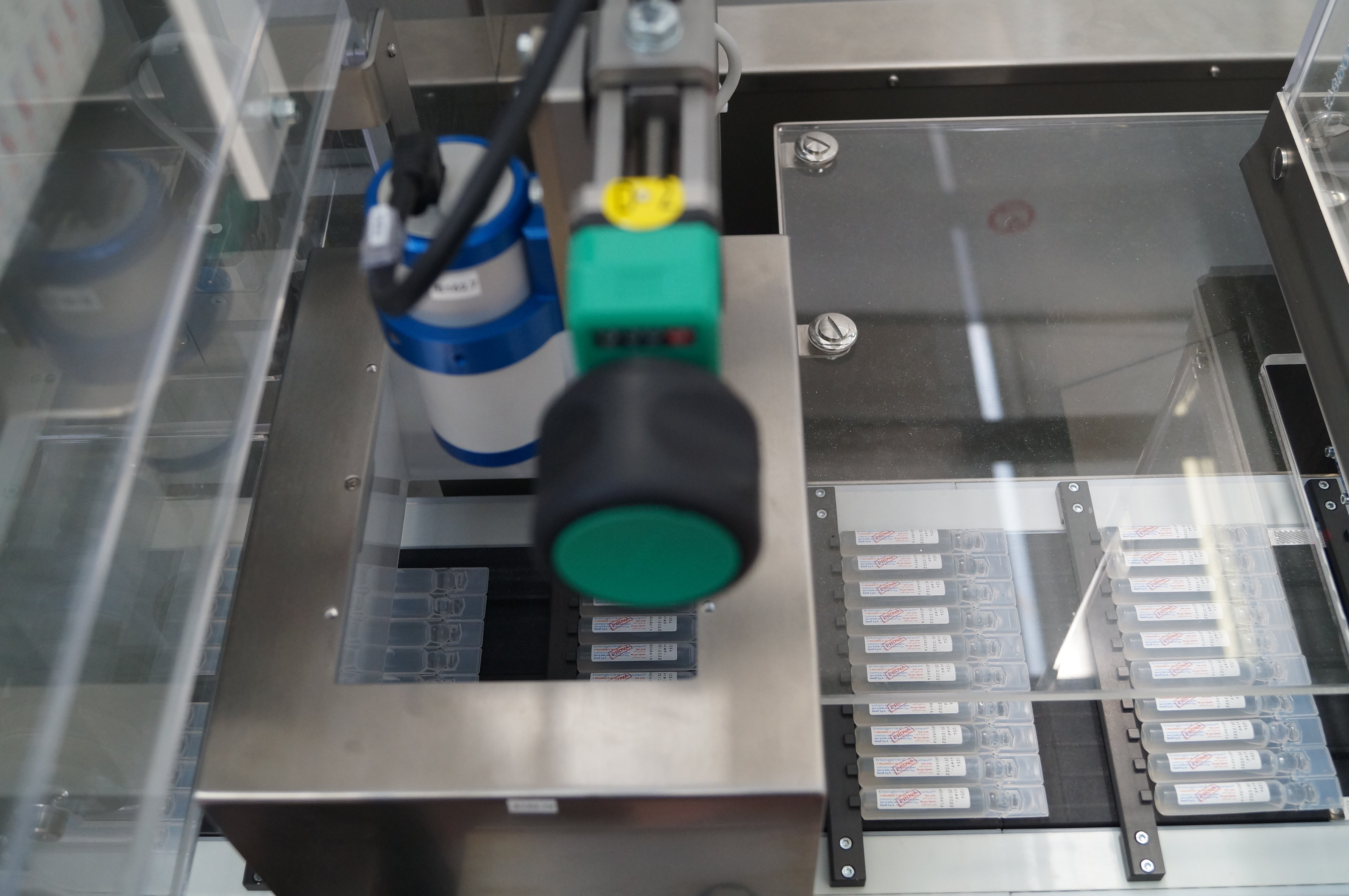

A dedicated camera verifies label presence on each bottlepack, rejecting unlabeled bottlepacks before cartoning.

Databox on Cartoner MA300

-

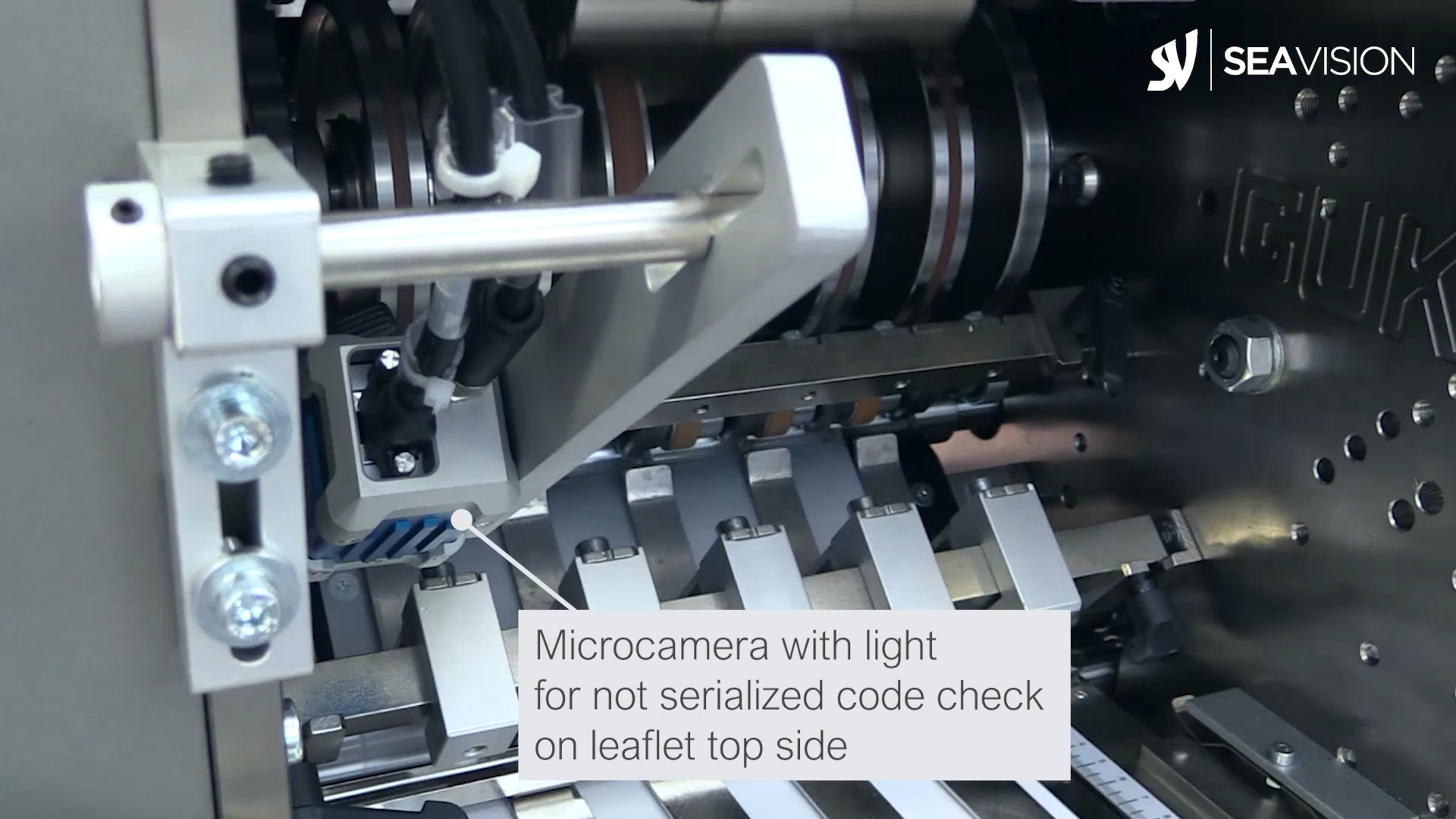

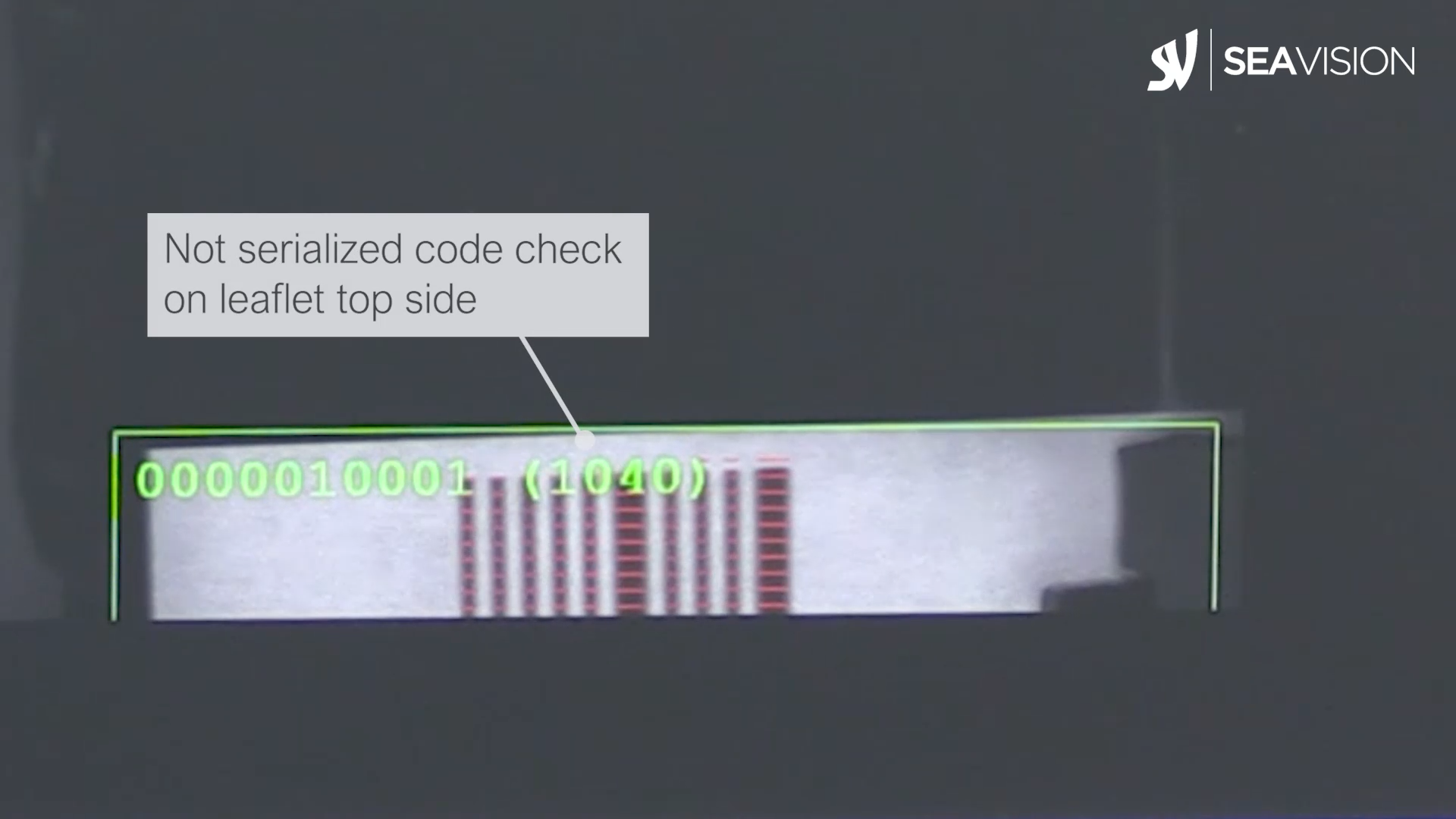

Non-Serialized Code Verification on Leaflets

A microcamera with integrated lighting verifies non-serialized data on the top side of leaflets. Incorrect leaflets are automatically rejected and will not reach the cartoning area.

-

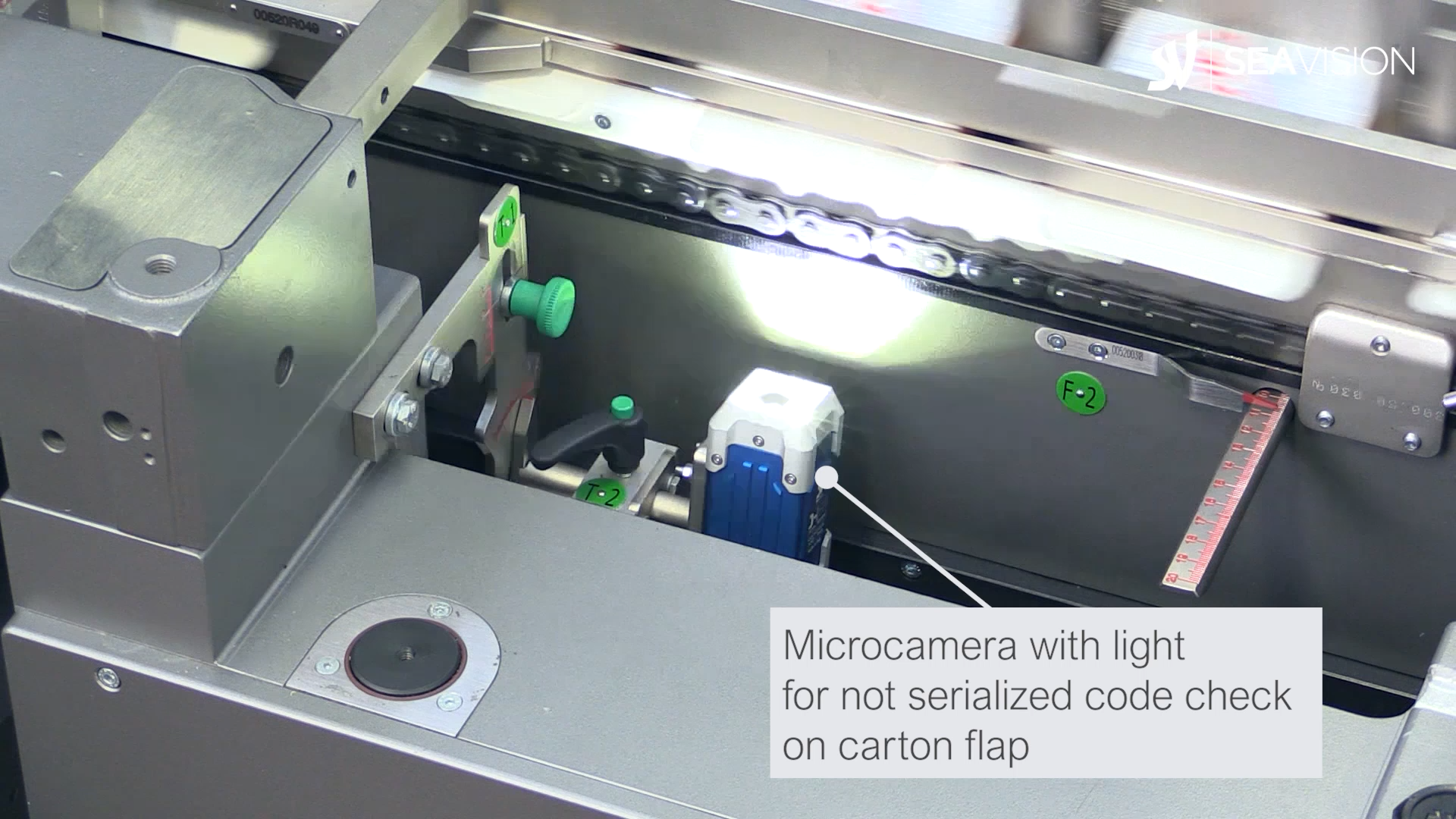

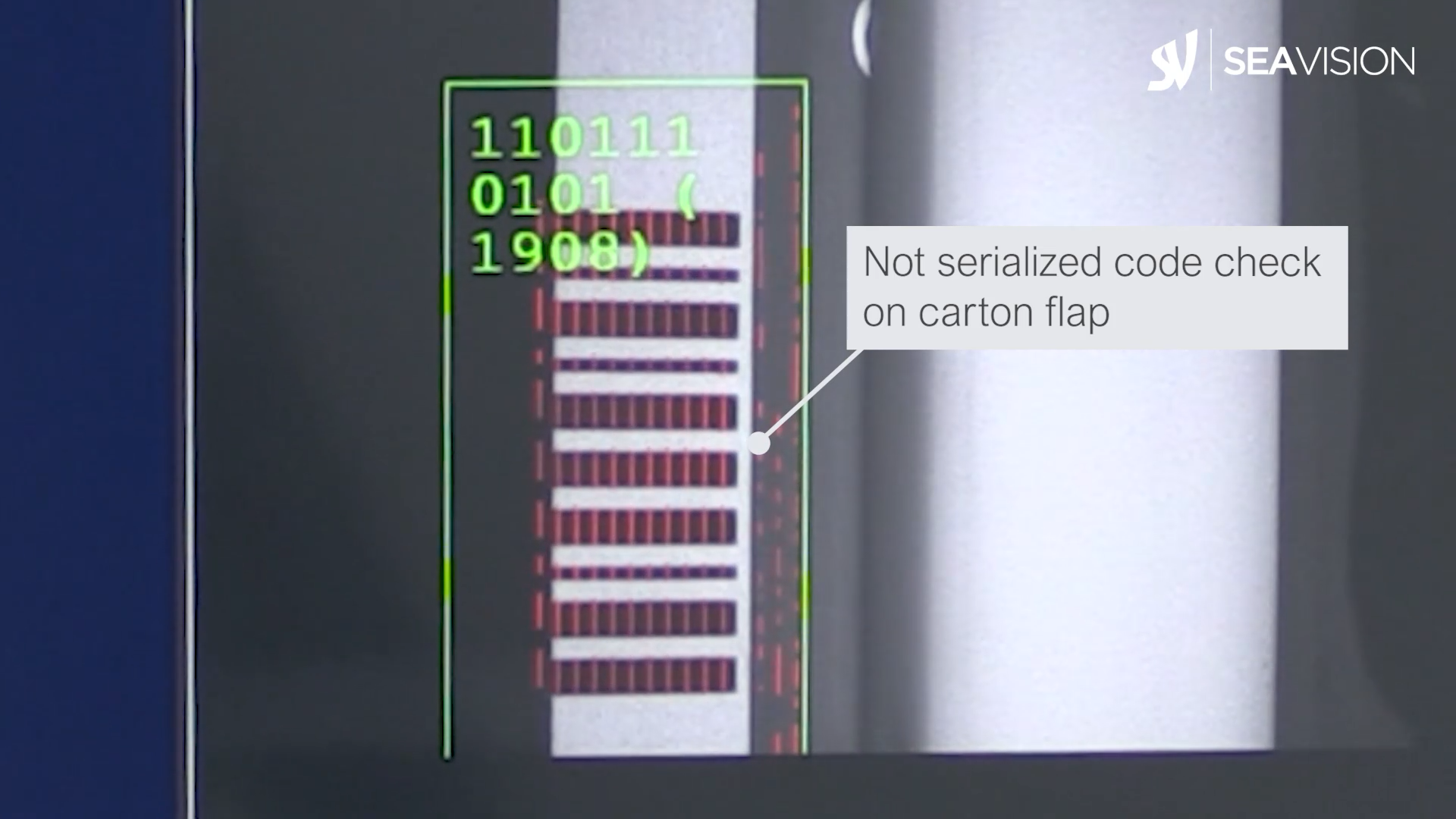

Non-Serialized Code Verification on Cartons

Another microcamera checks non-serialized codes on cartons, rejecting any with incorrect, non-readable or missing codes.

These integrated systems ensured continuous, automated, and precise inspection with minimal operational disruption.

Results

The implementation of SEA Vision’s solutions delivered:

-

Improved Product Quality

Automated inspections reduced labeling and coding errors significantly. -

Increased Efficiency

Minimized manual inspections and improved line throughput without compromising quality. -

Regulatory Compliance

Accurate verification ensured compliance with pharmaceutical packaging regulations, reducing risk of recalls. -

Operational Reliability

Consistent system performance with minimal downtime enhanced overall line productivity.

Other Applications

SEA Vision’s OCV Multi and Databox solutions are adaptable for integration across various labeling and cartoning machines to deliver scalable, precise, and compliant inspection capabilities within pharmaceutical packaging operations.

Learn More

For further information about SEA Vision’s OCV Multi and Databox solutions, visit:

.png?width=550&height=395&name=Senza%20titolo%20(1024%20x%20597%20px).png)