Ensuring flawless packaging is a priority in the cosmetics industry, where every detail speaks volumes about quality, authenticity and regulatory compliance. For premium serums packaged in glass bottles, even the laser-engraved text at the base of each bottle plays a crucial role. This marking confirms compliance standards, yet its subtlety makes it surprisingly difficult to detect: the engraving often blends with the glass, challenging both manual and automated inspection.

How can manufacturers reliably confirm the presence and accuracy of this base marking on every bottle, especially when production lines move at high speed and precision is non-negotiable?

This case study explores how a leading European cosmetics brand overcame this challenge with Databox, an advanced vision-inspection solution engineered to automate and streamline laser-text verification.

Challenges

The manufacturer required a fully automated inspection system capable of verifying the presence of laser markings on the base of each glass serum bottle. In the cosmetics industry, where packaging directly reflects product quality, there is growing pressure to guarantee that every detail is flawless. A missing or unreadable laser engraving isn’t just a minor defect; it can result in:

- Regulatory non-compliance, exposing the brand to fines or product recalls.

- Reputation damage, as consumers expect premium products to meet premium standards.

- Operational inefficiencies, since manual checks slow down throughput and increase labor costs.

Traditional inspection processes often depend on human operators, introducing variability, fatigue-related errors and inconsistent results. With production lines running thousands of bottles per day, manual verification is no longer feasible or reliable.

Solution

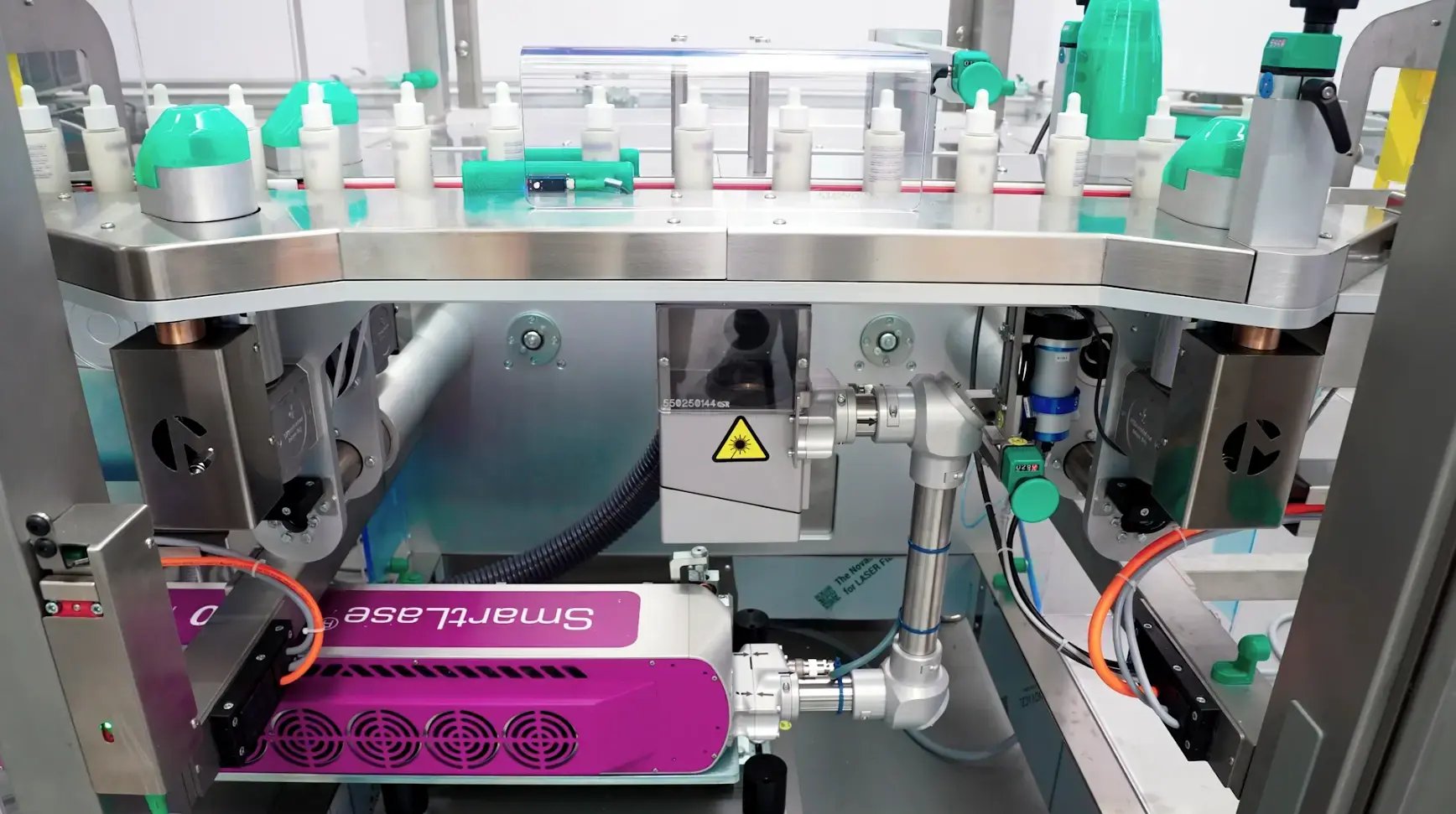

Databox is an advanced inspection platform designed to bring precision, speed, and reliability to packaging quality control. By automating laser-mark verification, it ensures that every glass bottle leaving the production line meets the highest quality and compliance standards.

Key Features

- Real-time presence & clarity check: instantly detects whether the laser-engraved text is present and readable, even on subtle or low-contrast markings.

- Seamless integration: installs easily on existing production lines, requiring no major modifications or downtime.

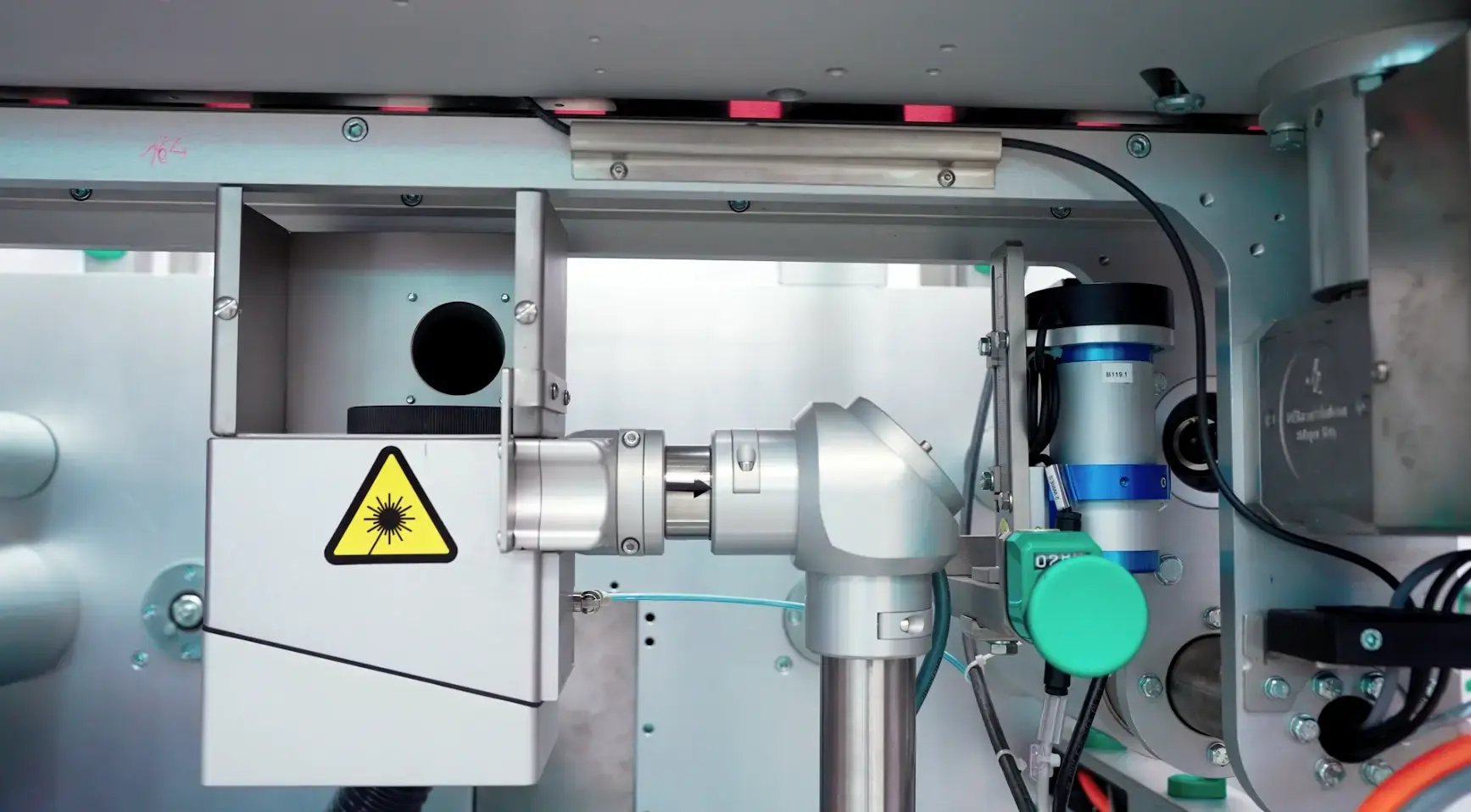

- Industrial miniaturized hardware: compact, robust components engineered for high-speed manufacturing environments.

- Customizable inspection logic: programmable measures allow full customization of inspection rules based on product type, marking style, or customer requirements.

- Consistent quality control: ensures optimal inspection across every product and material, maintaining uniform standards at scale.

How it works

The Databox inspection workflow is designed to be both simple and highly effective:

- Capture: a high-resolution industrial camera images the bottom of each glass bottle as it passes along the production line, ensuring consistent and precise visual data.

- Analyze: Databox instantly processes the captured image, verifying the presence and readability of the laser-engraved text using advanced vision algorithms.

- Alert: if the marking is missing, the system issues an immediate alert, enabling operators or automated reject mechanisms to remove the defective bottle before it continues downstream.

Benefits for cosmetics manufacturers

Integrating Databox into the production line brings clear, measurable value to cosmetics brands:

- Enhanced quality assurance: every bottle is verified with precision, ensuring flawless packaging that reinforces brand trust and meets strict regulatory requirements.

- Compliance with confidence: automated records and traceable inspection data simplify audits and support certification processes.

- Greater cost efficiency: by reducing waste, preventing recalls and minimizing manual checks, Databox lowers operational costs while improving throughput.

- Scalable performance: whether it’s a boutique skincare line or a high-volume global production facility, Databox adapts seamlessly to different manufacturing speeds and product formats.

Join us at Cosmopack 2026

In a cosmetics market where every detail influences customer trust, ensuring flawless packaging is essential, not optional. Automated inspection solutions like Databox give manufacturers the confidence that every bottle leaving the production line meets the highest standards of quality and compliance.

Ready to raise the bar on your packaging quality?

Reach out today and discover how Databox can modernize your inspection workflow and empower your brand with consistent, verifiable excellence or join us at Cosmopack 2026 in Bologna! We’ll be waiting for you at Stand A9 – Hall A9 from March 26 to 29, between 9:30 a.m. and 6:30 p.m., to showcase our latest cosmetic innovations.